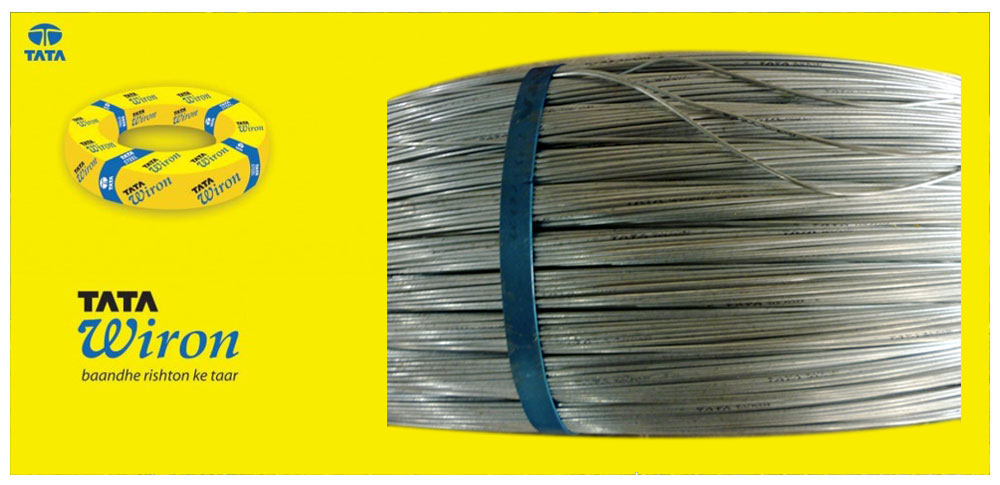

Tata Wiron - GI Wire

Tata Wiron Galvanized Iron (GI) wire is used in many different industries like agriculture plantations, shipyards etc. GI wire is strong & highly durable and easily identified because of the bright shine it usually holds. Farmers use it for providing support to plantations like Grapes, Tomato etc. and for fencing in their plantations.

Applications of GI Wire

- GI Wire used in vineyards & rubber plantations to provide support to plantation

- Manufacturer of fencing wire like products such as chain-link & barbed wire

- Manufacture of bail handles & bale tie-wire

- Used as stay wire & earthling wire

- Manufacture of wire meshes & gabion meshes

Strength of GI Wire

- Quality compatible to IS 280 & IS 4826 specification

- Excellent flexibility, softness and appropriate surface finish

- Consistency in coating & physical properties

- Pattern laid winding for proper coil packing

- No scale on wire resulting in faster completion of job due to smoother surface with no injuries

- World-class packing resulting in longer rust-proof shelf life

Benefits of GI Wire

- Total Protection : Galvanizing process reaches areas inaccessible to other similar processes for preventing rusting and corrosion

- Less Maintenance : GI Wires will never shrink or crack because it is metallurgical bonded to the steel it protects. It also offers superior resistance to abrasion and water

- Lowest First & Long Term Cost : GI Wires are lower in first & Long Term Cost than many other commonly specified protective coatings for steel

- Reliability : Coating life and performance are reliable and predictable

- Complete Protection : Zinc coating from galvanizing process is reasonably smooth and free from imperfections such as flux, ash & dross inclusions, black spots, pimples rust strains, bulky white deposits etc. and thus provide for the complete protection of the underlying cold rolled steel

- Ease of Inspection : Galvanized coatings are assessed readily by eye, and simple non-destructive thickness testing methods can be used