Tiscon Readybuild

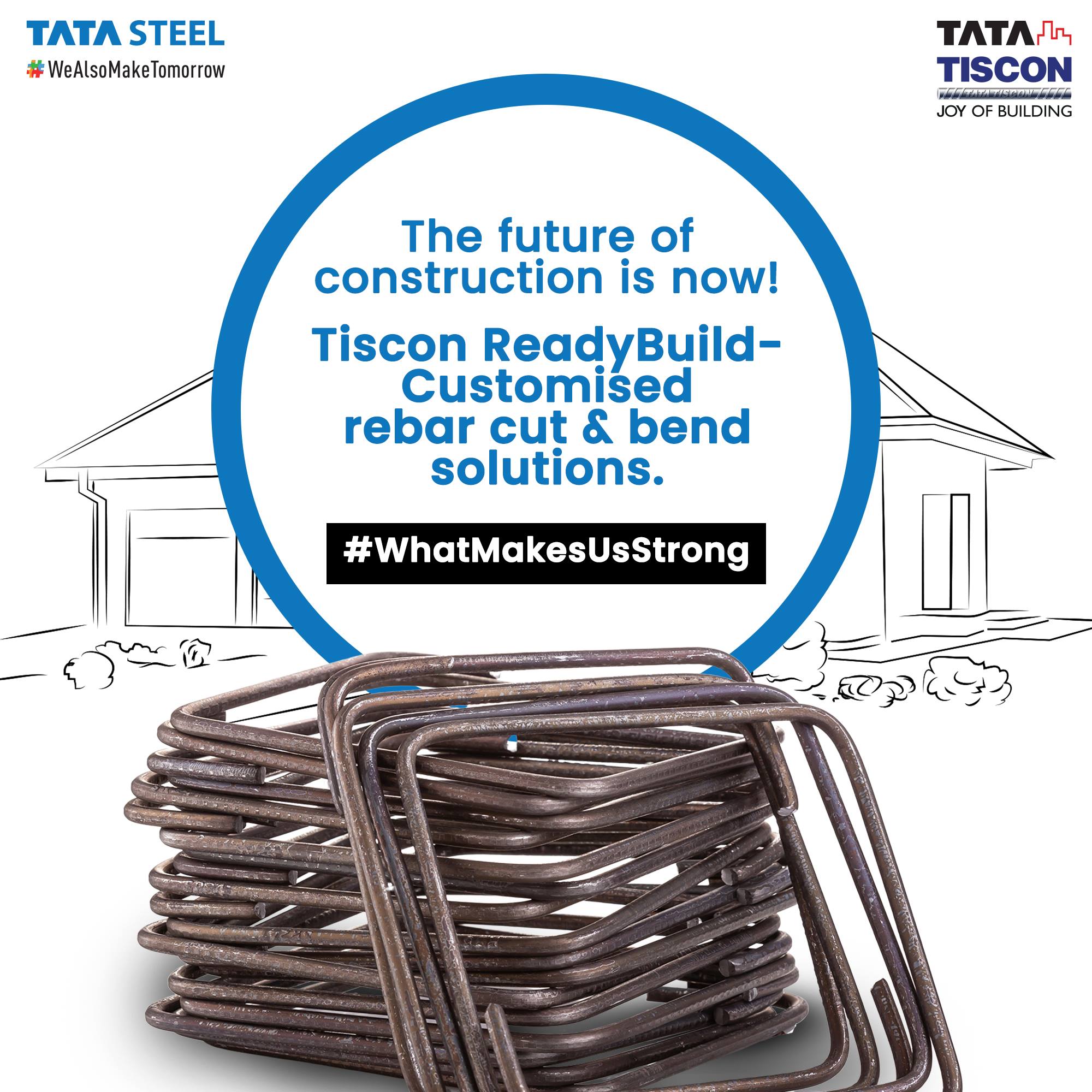

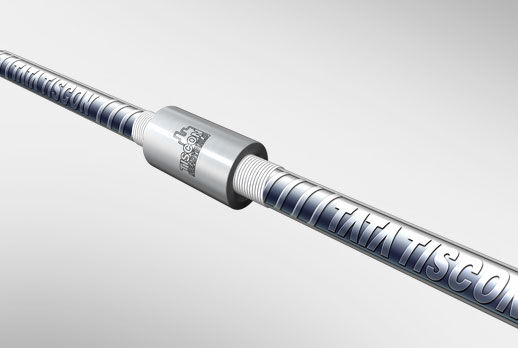

Tiscon ReadyBuild, a rebar downstream service presently offers the Cut & Bend (CAB), Couplers and BBS Development Services that aims at providing customized rebar shapes needed at the construction sites. The ReadyBuild Centers customize the lengths of the rebar and bend them at required angles in accordance with the project’s blueprint. It is capable of making the common shapes loops to complex helical shapes.

Applications of Tiscon Readybuild

- Wall to slab connection

- Beam to column connection

- Column-lap replacement

- Raft foundations

- Future extensions/additions

- Precast elements

Benefits of Tiscon Readybuild

- No Wastages : The cutting & bending process will be done at ReadyBuild Center, hence the wastages at the site becomes minimal and we take care of all the generated wastages

- Less Labor Hassles : Laborers at a construction site essentially perform two functions involving rebar; cutting and bending and tying. ReadyBuild will significantly reduce the dependence on the laborers for cut and bend activities

- Better Time Management : ReadyBuild is delivered on an "On Time in Full" policy; i.e. it will be delivered within 7 to 15 days after finalization of the design thereby significantly reducing pressure at the project manager's end to adhere to deadlines

- Unmatched Quality : Being a TATA Tiscon rebar, Readybuild is made from Virgin iron ore giving it superior strength and ductility than the secondary steel rebar in the market. It is also cut and bend by high accuracy machines

- Better Inventory Management : Owing to its customized design and "On time in full" delivery pattern, ReadyBuild is present just in time at site on requirement. This not only reduces the amount of space you need to utilize for keeping rebar, but also helps in saving costs associated with wastage, inventory and labor

- Easy Procurement : Readybuild is available in various lengths and diameters. Usually, the practice is to procure rebar for each requirement, then cut and bend at a later stage. Utilizing Readybuild, ensure that the procurement of rebar is inherently taken care of

- No Misplacing of Materials : ReadyBuild can be easily managed and its different shapes can be easily recognized with the use of identification tags

- Freedom in Design : The machines used to make ReadyBuild can transform any TATA Tiscon rebar into a shape imagined. Users have the freedom to design complex columns, pillars, ceilings being worry free on the rebar to be used

- Lower Working Capital : ReadyBuild brings with it a design suited to the project requirements thereby reducing the cost involved in cutting and bending by the laborers. ReadyBuild also keeps inventory costs to a minimum owing to the "On time in Full" delivery policy so that you save on real estate and overhead associated with wastage

- Timely Completion of Project : ReadyBuild's "On time in full" delivery policy and the help from two coordinators as part of the after sales team guiding the usage of the cut and bend steel rebar for usage ensures that construction ends on time with the best possible materials

- Strengthening of Brand : ReadyBuild sets the path for the timely completion of the project which is a key requirement for any promoter to envision the growth of their brand